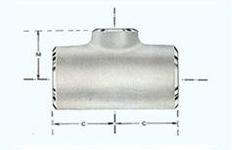

Butt Weld Tee - Unequal Tee Butt Weld Tee - Unequal Tee

Section Links : Equal Tee | Unequal Tee

Relying on innovation and advanced technology, we offer a wide range of precision engineered Unequal tees. Our ANSI B 16.9 grade Unequal tee fittings are made from well-tested metals and can withstand extremely high & low temperature conditions. These Unequal tees are offered by us in various metals, sizes and finishes to suit the pipe fitting demands of various industries. Proper mix of experienced team and latest machines allows us to customize these Unequal tees as per the specifications laid down by our clients.

We specialize in manufacturing and export of an extensive range of Unequal tee fittings, that are available in various standard and customized metals, sizes, dimensions and finishes to choose from. Optimization of top grade metals makes these Unequal tees capable of withstanding high pressure & temperature and resisting to corrosion. Our ANSI B 16.9 grade Unequal tee fittings are used to connect the pipes of different diameters and change the direction of pipe flow.

Riddhi Impex manufactures a wide range of tees (pipefitting) made of exotic metals, nickel, nickel alloys, Stainless Steel etc., of various grades. Tees (branch outlets) are manufactured as Unequal tees and Reducing tees. Unequal tees are exactly that, all three ends are of the same size. Reducing tees come with a combination of different outlet sizes.

Riddhi Impex manufactures & supplies high quality tees ( pipe fitting ) that can be used for various applications. Our tees are tested and verified for durability, accuracy and precision.

Riddhi Impex manufactures forged [ socket weld tee, forged threaded tees ], seamless & welded tees of types Unequal tee, reducing tees to ANSI B 16.9 from classes 2000 to 9000 and Schedules from 10 to 160 .

Riddhi Impex manufactures tees accordance with BS standard from classes 2000 to 9000 lbs, Schedule 10 to 160.

Riddhi Impex designs & manufactures tees (pipe fittings) of special type made according to drawing on request.

Material:

Carbon steel: ASTM A234 WPB, WPC, ASTM A420 WPL1, WPL3, WPL6 and WPHY-42/46/52/56/60/65/70

Stainless steel: ASTM A403 WP304/304L, WP316/316/L, WP321, WP347 and WPS31254

Alloy steel: ASTM A234 WP1/WP12/WP11/WP22/WP5/WP7/WP9/WP91

Duplex and super duplex steel: ASTM A815 UNS S31803/S32750/S32760

Special alloy steel: Monel400 and Inconel 600/800/825/C276, Ceramic Lined

Pressure: SCH5 to SCH160

Standard: ANSI B16.9/B16.28 and MSS SP-43/SP-75

Size range: 1/2 to 72 inches

Types: T, Pipe Tee, LT, Lateral tee , RT, Reducing tee

End Bevel: According to the bevel of welding pipe fittings construction

Surface treatment:Shot blasted, rust-proof black oil

INCHES |

METRIC |

N.B. |

O.D. At Bevel |

Run C |

Outlet M |

N.B. |

O.D. At Bevel |

Run C |

Outlet M |

Run |

Outlet |

Run |

Outlet |

|

|

Run |

Outlet |

Run |

Outlet |

|

|

½ ½ |

3/8 ¼ |

0.840 0.840 |

0.675 0.540 |

1 1 |

1 1 |

15 15 |

10 8 |

21.34 21.34 |

17.15 13.72 |

25.40 25.40 |

25.40 25.40 |

¾ ¾ |

½ 3/8 |

1.050 1.050 |

0.840 0.675 |

1 1/8 |

1 1/8 |

20 20 |

15 10 |

26.67 26.67 |

21.34 17.15 |

28.58 28.58 |

28.58 28.58 |

1 1/8 |

1 1/8 |

1 1 |

¾ ½ |

1.315 1.315 |

1.050 0.840 |

1 ½ 1 ½ |

1 ½ 1 ½ |

25 25 |

20 15 |

33.40 33.40 |

26.67 21.34 |

38.10 38.10 |

38.10 38.10 |

1 ¼ 1 ¼ 1 ¼ |

1 ¾ ½ |

1.660 1.660 1.660 |

1.315 1.050 0.840 |

1 7/8 |

1 7/8 |

32 32 32 |

25 20 15 |

42.16 42.16 42.16 |

33.40 26.67 21.34 |

47.63 47.63 47.63 |

47.63 47.63 47.63 |

1 7/8 |

1 7/8 |

1 7/8 |

1 7/8 |

1 ½ 1 ½ 1 ½ 1 ½ |

1¼ 1 ¾ ½ |

1.900 1.900 1.900 1.900 |

1.660 1.315 1.050 0.840 |

2 ¼ 2 ¼ 2 ¼ 2 ¼ |

2 ¼ 2 ¼ 2 ¼ 2 ¼ |

40 40 40 40 |

32 25 20 15 |

48.26 48.26 48.26 48.26 |

42.16 33.40 26.67 21.34 |

57.15 57.15 57.15 57.15 |

57.15 57.15 57.15 57.15 |

2 2 2 2 |

1 ½ 1 ¼ 1 ¾ |

2.375 2.375 2.375 2.375 |

1.900 1.660 1.315 1.050 |

2 ½ 2 ½ 2 ½ 2 ½ |

2 3/8 |

50 50 50 50 |

40 32 25 20 |

60.33 60.33 60.33 60.33 |

48.26 42.16 33.40 26.67 |

63.50 63.50 63.50 63.50 |

60.33 57.15 50.80 44.45 |

2 ¼ |

2 |

1 ¾ |

2 ½ 2 ½ 2 ½ 2 ½ |

2 1 ½ 1 ¼ 1 |

|

|

|

|

|

|

|

|

|

|

3 3 3 3 |

2 ½ 2 1 ½ 1 ¼ |

3.500 3.500 3.500 3.500 |

2.875 2.375 1.900 1.660 |

3 3/8 3 3/8 3 3/8 3 3/8 |

3 ¼ 3 2 7/8 2 ¾ |

80 80 80 80 |

65 50 40 32 |

88.90 88.90 88.90 88.90 |

73.03 60.33 48.26 42.16 |

85.73 85.73 85.73 85.73 |

82.55 76.20 73.03 69.85 |

3 ½ 3 ½ 3 ½ 3 ½ |

3 2 ½ 2 1 ½ |

4.000 4.000 4.000 4.000 |

3.500 2.875 2.375 1.900 |

3 ¾ 3 ¾ 3 ¾ 3 ¾ |

3 5/8 |

90 90 90 90 |

80 65 50 40 |

101.60 101.60 101.60 101.60 |

88.90 73.03 60.33 48.26 |

95.25 95.25 95.25 95.25 |

92.08 88.90 82.55 79.38 |

3 ½ |

3 ¼ |

3 1/8 |

BACK

|